SOLAR KERALA | MURICKENS GROUP

09447366779 | Enquiry | Send Mail

An ISO 9001:2015 Certified Company | 2018 Business Achievement Award Winner

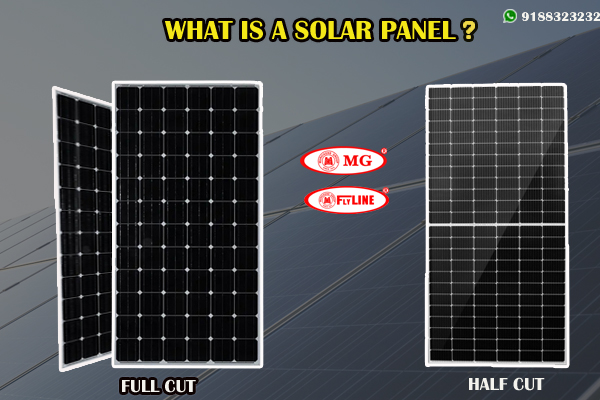

WHAT IS A SOLAR PANEL ?

Date : December 22, 2022

Solar panels collect sunlight, which is then converted into direct current (DC) electricity. Photovoltaic arrays can be used to generate solar electricity that supplies electrical equipment directly or feeds power back into an alternate current (AC) grid via an inverter system..

We use top-tier imported solar panels. Trina, JA Solar Panels, Canadian Solar Panels, Jinko, REC Solar Panels, and others are among them. It is a high-efficiency Mono PERC full and half-cut solar panel made with Advanced Robotic Technology.World-class solar panel manufacturers use fully robotic technology in their manufacturing processes, whereas local manufacturers typically use manual techniques. As a result, the efficiency of the local panel is lower when compared to the top ten world-class panels.

What is Half-Cut solar panel…?

Half-cut solar cells are divided into two halves (two solar panels fixed in a single frame). The top and bottom sections function independently. Even if the other is shaded, one portion is active. It is appropriate when the area is shaded. This improves the performance of the solar module. They are also referred to as "twin cells."

Working Mechanism:

The top ten world-class manufacturers use robotic technology throughout the manufacturing process. Solar modules are split in half here. Each half functions independently. That is, each unit operates independently and generates its own current. The primary benefit of half-cut solar panels is that they lower manufacturing costs.

Instead of the 600 W half cut, we can use the full cut of two panels (300 W x 2 = 600 W panel). Each individual unit has 300 W of power, so each panel requires 1.6 metres in length and 1 metre in width. In comparison to the 600 W half-cut single panel, this requires nearly double the space.

Manufacturers benefit the most from half-cut solar panels because they reduce manufacturing costs in areas such as frames, glass, and so on. Customers gain only one advantage in this manner: they save some installation space. The customer will be impacted if the panel sustains any damage. The manufacturers reap all of the benefits. In practise, full-cut small-wattage solar panels are far more useful and efficient than half-cut solar panels. However, in the future, the market availability of solar panels will be in the form of half cuts.

What is the Advantages of half-cut cell solar panels…?

• Half-cut solar cells are more useful to the manufacturers. It reduces a lot of risk factors, like cell breakage during the manufacturing time.

• This reduces manpower, maintenance, and fabrication costs( cost of glass, frames etc).

• One portion is active even if the other half is shaded.

• It not only cuts the cells in half but also reduces them overall manufacturing costs.

• Panel rates are calculated as per watts. It helps manufacturers to produce high capacity panels that can be accommodated in a limited space.

• On the customer side, the main benefit is to save installation space slightly.